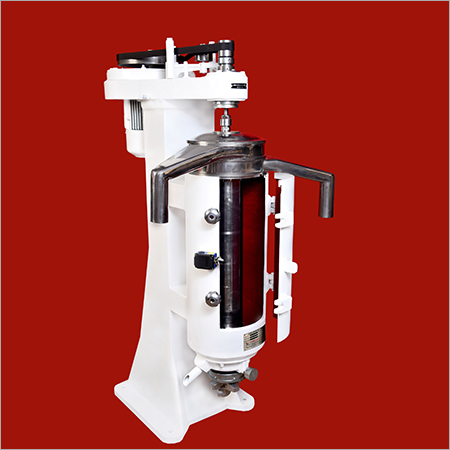

Biomass Separation Centrifuge Machine

Price 3500000 INR/ Unit

Biomass Separation Centrifuge Machine Specification

- Product Type

- Biomass Separation Centrifuge Machine

- Material

- High Grade Stainless Steel

- Type

- Industrial Laboratory Centrifuge

- Centrifugal Chamber

- Corrosion Resistant Stainless Steel

- Motor

- High Efficiency Electric Motor

- Refrigeration System

- Not Included

- Temperature Control Range

- Ambient to 40C

- Speed

- Up to 8000 RPM

- Dimension

- 1200mm x 700mm x 1100mm

- Capacity

- 10-50 Liters per Batch

- Safety Features

- Lid Interlock, Overheating Protection

- Weight

- Approx. 220 Kg

- Operation Mode

- Automatic and Manual

- Display

- Digital Control Panel

- Noise Level

- <70 dB

- Power Supply

- 220V/380V, 50/60Hz

Biomass Separation Centrifuge Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 1 Months

- Packaging Details

- Wooden Packaging

About Biomass Separation Centrifuge Machine

The Biomass Separation Centrifuge Machine can be used as a central process step in industrial biotechnology. Apart from this they are made from high grade components using high end technology & modern machinery. The Biomass Separation Centrifuge Machine can be used in various industries such as chemical, pharmaceutical, food, & other areas. They are also tested by our quality assurance team to ensure they are free form defects or flaws that may arise during manufacturing. Further our customers can avail these machines at market leading price.

Specification

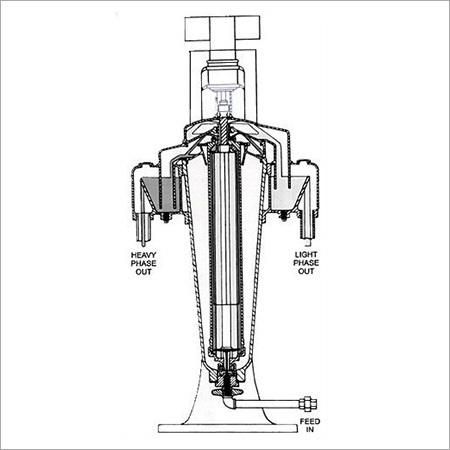

| Speed | 15000 Rpm |

| Type | Tubular Bowl Centrifuge |

| Model Number | AS26 SP |

| Capacity | 7 Kg Bowl Dust Holding Capacity |

| Material | MS |

| Brand | Vaishanvi Enterprises |

| Phase | 3 |

| Usage/Application | Bio Mass Separtion,Ink Separation,Industrial Wax Purification,Food Processing,Flavours Industry |

| Motor Power | 4Hp |

| Temperature | Ambient |

| Tube Capacity | Tube / Bowl Capacity 9Ltrs |

| Warranty | 1Year |

| Frequency | 50 Hz |

| Is It Portable | Non Portable |

| Noise Level | Normal |

| Voltage | 415 V |

| I deal in | New and Second Hand |

Precision Engineered for Industrial Strength

Built with high-grade stainless steel and a corrosion-resistant centrifugal chamber, this centrifuge ensures both longevity and reliability. Its robust construction supports rigorous laboratory and industrial use, making it suitable for a variety of biomass separation processes.

Enhanced Usability and Control

With options for automatic and manual operation, users can easily tailor settings via the intuitive digital control panel. The machines design facilitates straightforward batch loading and efficient separation, making it user-friendly for technicians and scientists alike.

Prioritizing Safety and Low Noise

Safety features such as lid interlock and overheating protection are integral to the centrifuge, ensuring secure operation at all times. Additionally, its operation remains consistently below 70 dB, supporting a quieter work environment.

FAQs of Biomass Separation Centrifuge Machine:

Q: How does the Biomass Separation Centrifuge Machine function during separation processes?

A: The centrifuge operates by spinning biomass suspensions at speeds up to 8000 RPM, using centrifugal force to separate solid and liquid components efficiently. Both automatic and manual operational modes are accessible through the digital control panel.Q: What are the main benefits of using this centrifuge in industrial or laboratory settings?

A: Key benefits include high separation efficiency, versatile capacity (1050 liters), low operational noise, robust stainless steel construction for durability, and multiple safety features for secure operation, making it suitable for demanding applications.Q: When is manual operation mode most appropriate for this centrifuge?

A: Manual mode is typically preferred for delicate procedures requiring operator oversight or when customizing speed and cycle parameters for unique biomass separation needs, offering greater flexibility in specialized applications.Q: Where is this centrifuge most effectively utilized?

A: This centrifuge is ideal for use in industrial laboratories, research institutions, biotechnological production facilities, and environmental analysis labs where processing moderate to large batch sizes is essential.Q: What process controls are available, considering temperature and safety requirements?

A: Users can monitor and manage operational parameters via the digital control panel, controlling temperature between ambient and 40C, and relying on built-in safety mechanisms like lid interlock and overheating protection for safe, reliable operation.Q: How should the machine be maintained to ensure long-term performance?

A: Routine cleaning of the chamber and regular inspection for wear, especially on seals and moving parts, are recommended. Ensuring the unit is free from chemical residues and promptly addressing alerts from the digital panel help maintain optimal functionality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifuge Machine Category

Biodiesel Centrifuge

Price 3500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Product Type : Other, Industrial Centrifuge

Type : Other, Vertical Centrifuge

Speed : Up to 6000 RPM

Tubular Bowl Centrifuge

Price 3500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Product Type : Other, Tubular Bowl Centrifuge

Type : Other, Automatic

Speed : 1500020000 RPM

Industrial Wax Separation Centrifuge Machine

Price 350000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel 304

Product Type : Other, Industrial Wax Separation Centrifuge Machine

Type : Other, Horizontal Basket Centrifuge

Speed : Up to 3000 RPM

Industrial Centrifuge Machine

Price 350000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Product Type : Industrial Centrifuge Machine

Type : Ultra Centrifuges

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free