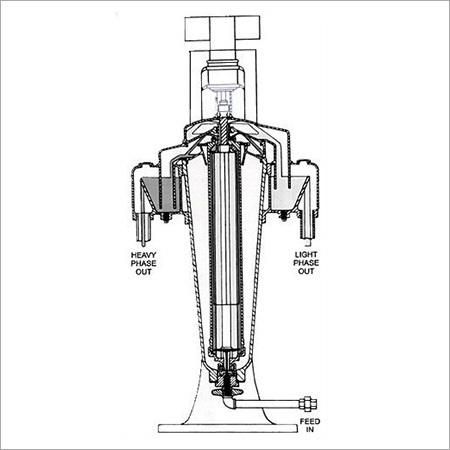

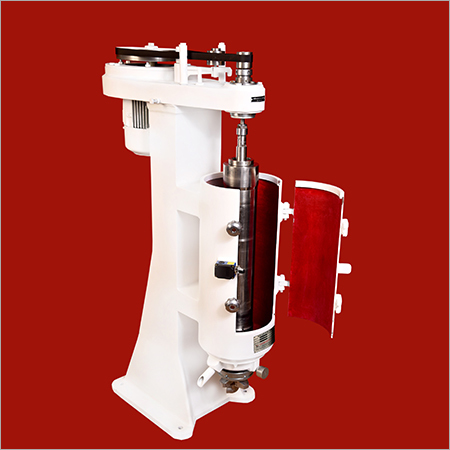

Tubular Bowl Centrifuge

Price 3500000 INR/ Unit

Tubular Bowl Centrifuge Specification

- Product Type

- Tubular Bowl Centrifuge

- Material

- Stainless Steel

- Type

- Automatic

- Centrifugal Compressor

- Not Included

- Centrifugal Chamber

- Tubular Bowl Type

- Motor

- 3 HP Electric Motor

- Refrigeration System

- Not Equipped

- Speed

- 1500020000 RPM

- Separation Factor (RCF)

- up to 16,000 × g

- Bowl Volume

- 6 to 7 liters

- Noise Level

- Below 70 dB

- Maximum Feed Capacity

- 300-500 liters/hour (varies by model and application)

- Weight

- about 260 kg

- Feed/Discharge System

- Continuous feed with manual solids removal

- Bowl Diameter

- approx. 125 mm

- Dimensions (L×W×H)

- approx. 600×700×1600 mm

- Application

- Used for clarification and separation of liquids with small solid content

Tubular Bowl Centrifuge Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Packaging Details

- wooden packing

- Main Domestic Market

- All India

About Tubular Bowl Centrifuge

We are a prime manufacturer and supplier of a wide exhibit of Tubular Bowl Centrifuge. Our offered array of separation equipment is known to have predominant execution, exactness and service life. The products simple operations and

Specification

| Brand | Vaishnavi Enterprises |

| Speed | 15000 Rpm |

| Type | Tubular Bowl Centrifuge |

| Model Number | AS16 |

| Capacity | Bowl Dust Holding Capacity 3.5Kg |

| Color | As per requirement |

| Material | MS |

| Voltage | 415 V AC |

| Phase | 3 Phase |

| Frequency | 50 Hz |

| Usage/Application | Bio Mass Separtion, Ink Separation, Industrial Wax Purification, Food Processing, Flavours Industry |

| Motor Power | 2Hp |

Efficient Liquid Clarification

The tubular bowl centrifuge excels in removing fine suspended solids from liquids, making it crucial for industries requiring high purity levels. Its design ensures continuous operation with high separation efficiency, benefiting the pharmaceutical, chemical, and food industries.

Robust and User-Friendly Design

Crafted from robust stainless steel, this centrifuge combines reliability with ease of maintenance. The continuous feed system streamlines the separation process, while manual solids removal allows for straightforward operation and cleaning. Its low noise level adds to its user comfort.

Flexible Industrial Applications

This centrifuge is suitable for diverse applications such as biotechnology, pharmaceuticals, edible oils, and more, handling feed capacities of up to 500 liters per hour. Its high-speed performance ensures quick and effective separation, even for liquids with small solid contents.

FAQs of Tubular Bowl Centrifuge:

Q: How does the tubular bowl centrifuge achieve high separation efficiency?

A: The centrifuge uses high rotational speedsbetween 15,000 and 20,000 RPMcreating a strong centrifugal force (up to 16,000 g) to rapidly separate small solid particles from liquids, ensuring precise clarification.Q: What types of materials can be processed in this tubular bowl centrifuge?

A: It is suitable for processing liquids containing small quantities of suspended solids, making it ideal for pharmaceutical preparations, biotechnology processes, edible oil clarification, and similar applications.Q: When should solids be manually removed from the centrifuge?

A: Solids should be manually removed from the bowl once the separation process is complete or once the bowls capacity is reached. The frequency depends on the solid load in the feed material.Q: Where is this centrifuge typically installed?

A: Due to its dimensions and weight (approx. 6007001600 mm; 260 kg), it is usually installed in laboratories, production plants, or processing facilities that require continuous, automatic liquid-solid separation.Q: What is the operation process of this centrifuge?

A: Liquid feed continuously enters the spinning tubular bowl, where centrifugal force separates solids from the liquid. The clarified liquid is discharged, while solids accumulate inside the bowl for later manual removal.Q: How does the system benefit industrial users?

A: Its automatic operation, high throughput of up to 500 liters/hour, and strong separation factor boost productivity, enhance product purity, and simplify fluid-solid separation processes, leading to time and cost savings.Q: Is the centrifuge equipped with a refrigeration system?

A: No, this model does not feature a refrigeration system, making it best suited for applications that do not require temperature-controlled separation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifuge Machine Category

High Speed Tubular Bowl Centrifuge

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Vertical Centrifuge

Material : SS

Product Type : Other, High Speed Tubular Bowl Centrifuge

Usage : Industrial

Biodiesel Centrifuge

Price 3500000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Vertical Centrifuge

Material : Stainless Steel

Product Type : Other, Industrial Centrifuge

High Speed Tubular Bowl Centrifuge

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Centrifugal Separator

Material : Stainless Steel (SS 304/316)

Product Type : Other, High Speed Tubular Bowl Centrifuge

Industrial Centrifuge Machine

Price 350000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Ultra Centrifuges

Material : Stainless Steel

Product Type : Industrial Centrifuge Machine

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS