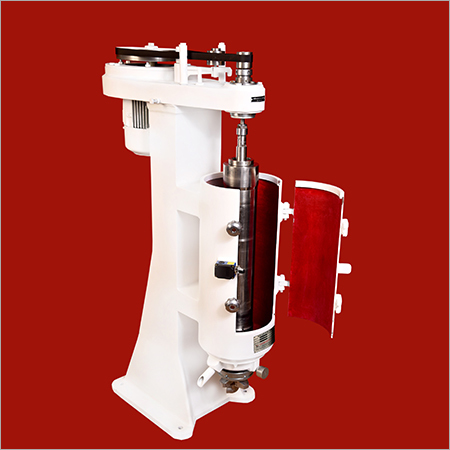

Ink Clarification Centrifuge Machine

Price 3500000 INR/ Unit

Ink Clarification Centrifuge Machine Specification

- Product Type

- Ink Clarification Centrifuge Machine

- Material

- Stainless Steel

- Type

- Automatic, Industrial Grade

- Centrifugal Compressor

- Not Applicable (Uses centrifugal action, not compressor)

- Centrifugal Chamber

- High-grade Stainless Steel, Corrosion Resistant

- Motor

- Heavy Duty Induction Motor, 2-5 HP

- Refrigeration System

- Not Equipped (Machine operates at ambient temperature)

- Temperature Control Range

- Ambient, not temperature controlled

- Speed

- 3000-5000 RPM (Variable)

- Application

- Used for clarification and filtration of industrial inks

- Discharge Type

- Manual/Automatic solid discharge options

- Dimension

- Customizable as per capacity and client requirements

- Safety Features

- Interlock system, Overload protection, Emergency stop

- Operation

- Fully Automatic

- Weight

- Approx. 150-400 kg, depending on model

- Noise Level

- Low noise operation (<65 dB)

- Separation Type

- Solid-Liquid Separation

- Maintenance

- Easy to clean and maintain

- Capacity

- 10-50 Litres per batch (Depending on model)

- Voltage

- 220V/380V, 50Hz/60Hz

- Control Panel

- Digital with programmable settings

Ink Clarification Centrifuge Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 1 Months

- Packaging Details

- Wooden Packaging

- Main Domestic Market

- All India

About Ink Clarification Centrifuge Machine

Based in Dombivli, Maharashtra, we are engaged in business of manufacturing and supplying top quality Ink Clarification Centrifuge Machine. A centrifuge is a machine that has a chamber capable to rotate at high speeds, eliminating any kind of contaminant particles from fluid fed into it. It can easily remove moisture, dissolved gases, and solid particles from ink. This machine has a large chamber that can hold a large amount of ink for cleaning purpose. Ink Clarification Centrifuge Machine is available in various capacities as per your applications.

Features:

-

High-speed motor

-

Energy efficient operation

-

Compact size

Advanced Clarification and Filtration Efficiency

This centrifuge machine utilizes high-speed centrifugal action (30005000 RPM) to deliver rapid and effective separation of solids from industrial inks, enhancing the purity and consistency required in ink processing. Its flexible configuration supports both manual and automatic discharge, accommodating different operational preferences.

User-Friendly Digital Controls and Customization

An intuitive digital control panel with programmable settings allows operators to precisely manage the filtration process. The machine can be custom-built in terms of dimensions and capacity, ensuring seamless integration into existing workflows and maximizing productivity based on client needs.

Safety-Focused Industrial Design

Incorporating essential safety measures such as interlock systems, overload protection, and emergency stop buttons, this centrifuge prioritizes the well-being of operators. Stainless steel construction also ensures durability and resistance to corrosion, ensuring longevity even in demanding environments.

FAQs of Ink Clarification Centrifuge Machine:

Q: How does the Ink Clarification Centrifuge Machine separate solids from liquid inks?

A: The machine employs rapid centrifugal force, spinning at variable speeds (30005000 RPM). This process causes solid particles within the ink to move outward and separate from the liquid, yielding clarified ink with consistent quality.Q: What types of inks and industries can benefit from this centrifuge?

A: It is suitable for a wide range of industrial inks used in printing, manufacturing, and related sectors. Industries requiring efficient solid-liquid separation for ink purification and filtration will find this machine highly beneficial.Q: When should the centrifuge be cleaned and maintained?

A: For optimal performance and hygiene, the centrifuge should be cleaned after each batch or as per the maintenance schedule recommended in the operating manual. Its design supports effortless disassembly for thorough cleaning.Q: Where can this centrifuge machine be installed?

A: The machine is designed for installation in industrial ink processing units, manufacturing facilities, and dedicated filtration areas. Its customizable dimensions allow it to fit various spatial requirements.Q: What process controls are integrated into the machine?

A: It features a digital control panel with programmable settings, enabling operators to adjust speed, operation time, and discharge mode according to the specific demands of each batch.Q: How does the discharge system work?

A: Depending on the model, the centrifuge offers either manual or automatic solid discharge. This allows operators to choose the most efficient and convenient method for removing separated solids.Q: What are the key benefits of using this centrifuge for ink processing?

A: The machine enhances ink quality through efficient solid-liquid separation, increases operational safety with modern protections, offers low-noise operation, and supports easy maintenancemaking it a reliable solution for industrial ink processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifuge Machine Category

High Speed Tubular Bowl Centrifuge

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Vertical Centrifuge

Product Type : Other, High Speed Tubular Bowl Centrifuge

Material : SS

Motor : 3 HP, Three Phase

Biodiesel Centrifuge

Price 3500000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Vertical Centrifuge

Product Type : Other, Industrial Centrifuge

Material : Stainless Steel

Motor : 3 Phase Electric Motor

Purification Centrifuge Machine

Price 3500000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Benchtop, automatic

Product Type : Other, Purification Centrifuge Machine

Material : High grade stainless steel (SS304/316)

Motor : Brushless DC motor, variable speed

High Speed Tubular Bowl Centrifuge

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Centrifugal Separator

Product Type : Other, High Speed Tubular Bowl Centrifuge

Material : Stainless Steel (SS 304/316)

Motor : Electric, 15 HP (variable depending on model)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS