High Frequency Vibrating Screen

High Frequency Vibrating Screen Specification

- Type

- Vibrating Screen

- Material

- Stainless Steel / Mild Steel

- Processing Type

- Automatic

- Condition

- New

- Shape

- Rectangular

- Capacity

- 1 to 10 TPH (Customizable)

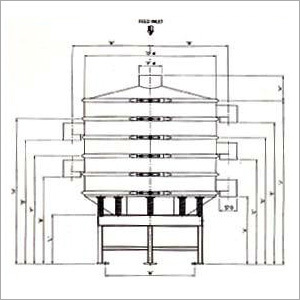

- Diameter

- 360-2000 mm (Model Dependent)

- Layer

- Upto 5 layers

- Dimension (L*W*H)

- Customizable / 1200 x 3000 mm (example)

- Power Mode

- Electric

- Voltage

- 220-240 V

- Power Consumption

- 2-5 kW

- Media

- Wire Mesh/PU Screen

- Noise Level

- Low (<75 dB)

- Frequency

- 3000 RPM (High Frequency)

- Application

- Screening, Separation, Grading, Dehydration in Mining, Mineral, Chemical, Food and Pharmaceutical industries

- Coating Type

- Powder Coated

- Screen Opening Size

- 0.074 - 10 mm (Customizable)

- Discharge Method

- Front/Bottom Discharge Port

- Motor Type

- Vibration Motor / Standard

- Screen Efficiency

- > 85%

- Installation

- Floor Mounted/Skid Mounted

- Feeding Size

- 10 mm

- Maintenance

- Easy to Maintain

- Drive Mode

- Dual Vibration Motors

- Weight

- 600-3000 kg (depends on model)

High Frequency Vibrating Screen Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 10-15 Days

- Sample Available

- Yes

- Main Domestic Market

- All India

- Certifications

- Wooden Packaging

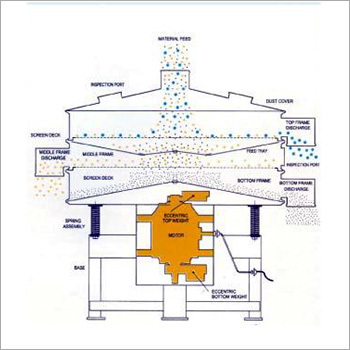

About High Frequency Vibrating Screen

We as a prime manufacturer and provider are occupied with offering best quality High Frequency Vibrating Screen. Generally respected for its sturdiness, it is a favored decision of our customers over other vibrating screens. This item finds an unfathomable application in power stations, mines, substance businesses, and coal dressing also. In addition to this, our array of High Frequency Vibrating Screen is effective in offering a bother free execution. Additionally, materials like sand, nourishment stuff, meat, flavors,

Specification

| Transmission Structure | Self-Centering Shaker |

| Type Of Machine | Circular |

| Material | Stainless Steel |

| Brand | Vaishnavi Enterprises |

| Automation Grade | Automatic |

| Size | 30 inch |

| Color | Any |

| Voltage | 415V AC |

Customizable Screening for Versatile Applications

Built to address a range of screening needs, this vibrating screen supports diverse applications across mining, mineral, chemical, food, and pharmaceutical industries. Its adaptable screen size and capacity options, along with optional wire mesh or PU screen media, ensure tailored solutions for different material characteristics and processing requirements.

High Efficiency and Low Noise Performance

Powered by high-frequency vibration at 3000 RPM, the unit delivers over 85% screening efficiency while maintaining a low noise level below 75 dB. This design optimizes productivity and creates a safer, more comfortable workplace environment. The robust construction minimizes downtime, ensuring reliable operation and longevity.

FAQs of High Frequency Vibrating Screen:

Q: How does the High Frequency Vibrating Screen ensure efficient material separation?

A: The screen achieves high efficiency (greater than 85%) by using dual vibration motors operating at 3000 RPM. This high-frequency mechanism, combined with customizable screen openings, allows precise separation, grading, and dehydration of materials with feeding sizes up to 10 mm.Q: What industries can benefit from using this vibrating screen model?

A: This vibrating screen is ideally suited for the mining, mineral processing, chemical, food, and pharmaceutical industries, offering solutions for screening, separation, grading, and dehydration tasks with flexibility for various material types.Q: When should I choose a wire mesh versus a PU screen media?

A: Wire mesh is typically preferred for dry, fine, or abrasive materials that require high-strength screening, while PU screens offer enhanced durability and are ideal for moist, sticky, or highly corrosive processing environments. The choice depends on your specific application and material properties.Q: Where can this vibrating screen be installed?

A: The equipment can be installed on the factory floor or mounted on a skid, providing flexibility to integrate seamlessly with your production layout. Its customizable dimensions allow for tailored installation in diverse operational settings.Q: What maintenance processes are required for this equipment?

A: Maintenance is straightforward due to the accessible design and quality powder-coated finish. Routine checks of vibration motors, screen tension, and periodic cleaning ensure optimal performance and extend equipment life.Q: What benefits does dual vibration motor drive offer compared to single drive models?

A: Dual vibration motors provide balanced force distribution for higher screening efficiency and uniform material movement, reducing maintenance requirements and minimizing vibration-induced wear on the screen body.Q: How customizable are the size, capacity, and discharge options of this vibrating screen?

A: The screen offers extensive customization, with screen sizes from 360 to 2000 mm diameter, capacities from 1 to 10 TPH, up to 5 screening layers, and selectable discharge options (front or bottom) to match your precise material handling and process needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Category

Circular Vibrating Screen

Price Range 100000.00 - 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Customized

Capacity : 2 800 TPH

Type : Other, Circular Vibrating Screen

Material : Other, Mild Steel/Stainless Steel

Vibrating Screen Separator

Price Range 100000.00 - 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : As per machine model

Capacity : 1001200 kg/hr

Type : Other, Rotary Vibrating Screen Separator

Material : Stainless Steel

Industrial Vibrating Screen

Price Range 100000.00 - 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Customized / 1200 x 900 x 1200 mm

Capacity : Up to 5000 kg/hr

Type : Other, Vibrating Screen

Material : Other, Stainless Steel / Mild Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free