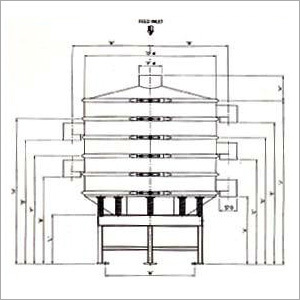

Industrial Vibrating Screen

Industrial Vibrating Screen Specification

- Type

- Vibrating Screen

- Material

- Stainless Steel / Mild Steel

- Processing Type

- Vibratory

- Condition

- New

- Shape

- Round

- Capacity

- Up to 5000 kg/hr

- Diameter

- 600 mm - 1800 mm

- Layer

- Single / Double / Multiple Layers

- Dimension (L*W*H)

- Customized / 1200 x 900 x 1200 mm

- Power Mode

- Electric

- Voltage

- 220 V / 380 V

- Power Consumption

- 1.5 kW - 5.5 kW

- Media

- Solid / Powder / Granules

- Noise Level

- Low

- Frequency

- 50 Hz / 60 Hz

- Application

- Industrial Screening, Separation, Sizing

- Coating Type

- Powder Coated

- Automation Grade

- Semi-Automatic / Automatic

- Discharge Outlet

- Multiple Discharge Ports

- Maintenance

- Easy Service Access

- Screen Material

- Stainless Steel Wire Mesh

- Feeding Size

- 10 mm

- Mobility

- Fixed or Portable Options

- Vibration Type

- Horizontal Circular Motion

- Screen Mesh Size

- 10 mesh to 500 mesh

- Operating Temperature

- Up to 80C

- Installation Type

- Stand-Alone / Inline

- Drive Type

- Motor Driven

- Service Life

- Long Lasting

Industrial Vibrating Screen Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 10-15 Days

- Packaging Details

- Wooden Packaging

- Main Domestic Market

- All India

About Industrial Vibrating Screen

Industrial Vibrating Screen

With years of involvement in this domain, we as a prominent manufacturer and provider have cut a specialty for ourselves, in offering Industrial Vibrating Screen. These vibro screens are accessible in electromagnetic sort and mechanized sort and for scalping, cleaning, isolating and measuring different sorts of mass material. Offered vibro screens are fabricated with best grade material and current innovation. Our customers can avail best quality array of Industrial Vibrating Screen from us at sensible costs.

Specification

|

Transmission Structure |

Self-Centering Shaker |

|

Type Of Machine |

Circular |

|

Material |

Stainless Steel |

|

Brand |

Vaishnavi Enterprises |

|

Automation Grade |

Automatic |

|

Size |

30 inch |

|

Color |

Any |

|

Voltage |

415V AC |

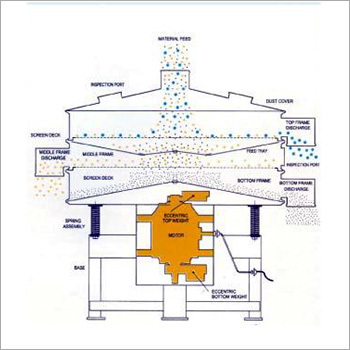

Reliable Screening for Diverse Applications

Engineered for screening, separation, and precision sizing, the vibrating screen processes solids, powders, and granules across numerous industries. Multiple discharge ports and mesh configurations ensure seamless integration into your production workflow. The equipment is designed to withstand heavy-duty use, supported by a sturdy stainless steel or mild steel frame and a powder-coated finish for lasting performance.

Flexible Design with Enhanced Efficiency

Available in various sizes and customizable setups, this screen offers single, double, or multiple layers to meet your processing needs. Portable or fixed models and adjustable mesh sizes (10 to 500 mesh) provide adaptability for diverse applications. Electric operation with low power consumption ensures efficient and economical performance.

User-Friendly Operation and Maintenance

With semi-automatic or automatic options, straightforward installation (stand-alone or inline), and easy service access, downtime is minimized. The unit operates quietlyeven at high capacities up to 5000 kg/hrmaking it suitable for environments where noise abatement is vital. Its simple maintenance requirements further support continuous, long-term use.

FAQs of Industrial Vibrating Screen:

Q: How does the industrial vibrating screen ensure efficient separation and sizing?

A: The screen utilizes a motor-driven horizontal circular vibration, adapting to different mesh sizes (10 to 500 mesh), layer configurations (single/multiple), and adjustable feed sizes up to 10 mm. This flexible design ensures accurate separation and optimal sizing for a broad spectrum of solid, powder, or granular materials.Q: What materials can be processed using this vibrating screen?

A: This vibrating screen is suitable for processing a variety of materials, including solids, powders, and granules. Its robust stainless steel wire mesh and multiple discharge ports make it ideal for industrial applications requiring precise screening, separation, and sizing.Q: When is it appropriate to use a fixed versus a portable model?

A: A fixed model is ideal for permanent, high-throughput production setups, while the portable option is suited for operations requiring frequent relocation or varying site requirements. Both types deliver stable performance and are available in different dimensions to fit specific space constraints.Q: Where can the vibrating screen be installed within my production line?

A: The vibrating screen offers stand-alone or inline installation, enabling easy integration into new or existing production lines. Its customizable dimensions and discharge configurations support a wide range of facility layouts and workflow requirements.Q: What is the maintenance process for this equipment?

A: Maintenance is straightforward thanks to the easy-access design, allowing for quick mesh replacement and cleaning. The powder-coated surface and durable construction also minimize wear and corrosion, promoting long service life with minimal downtime.Q: What are the operational benefits of this vibrating screen?

A: Beyond high efficiency and versatility, the screen features low noise levels, low power consumption (1.5 5.5 kW), and a long-lasting construction. The stainless steel or mild steel body, combined with a powder-coated finish, ensures enduring performance even in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Category

Circular Vibrating Screen

Price Range 100000.00 - 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Shape : Other, Round/Circular

Material : Other, Mild Steel/Stainless Steel

Media : Granules, Powder, Aggregate, Ore

Type : Other, Circular Vibrating Screen

Vibrating Screen Separator

Price Range 100000.00 - 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Shape : Other, Round

Material : Stainless Steel

Media : Granular / Powder / Liquid

Type : Other, Rotary Vibrating Screen Separator

High Frequency Vibrating Screen

Price Range 100000.00 - 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Shape : Other, Rectangular

Material : Other, Stainless Steel / Mild Steel

Media : Wire Mesh/PU Screen

Type : Other, Vibrating Screen

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free